Application of Intelligent Electric Screwdrivers in Preventing Missing Fasteners on Production Lines

Consumers’ ever-growing demand for both quantity and quality in electronic products has placed new challenges on assembly-line productivity and fastening process control. Tightening screws is one of the most frequent and critical operations in electronics assembly; its efficiency and accuracy directly affect the throughput of the entire line. Today, most screw-driving stations still rely on manual work. A single product may require several different sub-assemblies, each needing multiple screws in various positions. Under prolonged, high-intensity labor, operators easily miss screws or fail to fasten them properly. Meanwhile, many plants rely on single-layer error-proofing schemes that are not very effective. Missing-screw defects therefore escape the station and reach customers, incurring both direct and indirect losses for the company.

The quality of an assembly line is largely determined by the error-proofing capability of its tools. Danikor’s intelligent electric screwdriver is specifically designed to prevent missing fasteners. It can set monitoring-angle thresholds for each failure mode, ensuring that no screw escapes detection for omission, insufficient torque, re-tightening, or thread stripping. Automatic screw feeding and driving are combined with high speed and low cost, effectively eliminating the problem of missing screws.

Real-time process monitoring allows the Danikor screwdriver to predict faults and adjust before damage occurs—crucial for delicate electronics. Torque, angle, and speed traces are captured continuously, and these data are analyzed to anticipate driver failures. The tool can handle different screw types, control the number of revolutions, and use a torque-angle tightening strategy to foresee omissions, floating screws, or stripped threads, thereby increasing fastening accuracy.

Compared with conventional electric screwdrivers, Danikor’s intelligent model offers three key advantages:

Infinitely variable speed: Driven by a servo motor, its rotational speed can be set anywhere within the rated range.

Easy torque adjustment: A built-in torque sensor provides real-time feedback, and torque values can be changed instantly via pre-programmed recipes when screws are swapped.

Built-in quality monitoring: An encoder on the rear of the servo motor measures rotation angle, and together with the torque sensor, enables precise assessment of each fastening.

Torque-Angle Tightening Strategy

Start-up: After the driver starts, it applies a preset seating torque.

Zero-Angle Reset: When real-time torque reaches the seating torque, the encoder resets the angle reading to 0°.

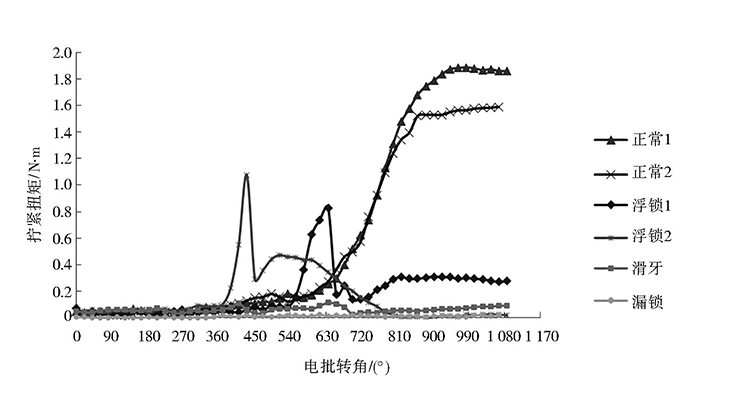

Tightening Phase: Over the next 0–1080° of rotation, the driver continuously compares torque vs. angle to determine whether the joint is normal, missing, floating, or stripped.

Curve Analysis & Alarm Logic

Floating (loose) screw: Torque reaches 0.7 N·m and triggers an alarm, yet the depth does not reach the specified value. Manual mode may be used to complete the tightening, producing the “floating” curve. Causes include burrs on the hole or screw, or raised surfaces on the workpiece.

Stripped thread: Torque never reaches the set value; the driver keeps advancing until a depth alarm is triggered.

Missing screw: The torque signature resembles that of a stripped thread (i.e., no meaningful torque), so it is classified under the same “strip/missing” alarm.

By analyzing these four torque-angle signatures, the Danikor intelligent electric screwdriver can issue the appropriate alarms and guarantee fastening quality.

In summary, the Danikor intelligent electric screwdriver not only automates the screw-driving process but also uses its torque-angle strategy to prevent missing screws on production lines. It ensures every screw is correctly installed and tightened, thereby improving assembly quality and customer satisfaction.